As PCB’s become more complex to keep up with today’s technology needs, designers must consider the role of critical nets and traces in order to obtain optimal signal performance of their design. A major contributor to ensuring your design is successful, is whether or not your impedance requirements are being met. This is no easy task as there are multiple design aspects that can affect your impedance, such as physical dimensions of your PCB, the chosen dielectric materials, board stack-up, and the trace and space widths as well as matching trace lengths.

In this webinar the design and DFM experts at EMA and Sierra Circuits will help you understand how to set up your design to meet your desired controlled impedance requirements while ensuring high yield and first pass success in manufacturing.

What you will learn:

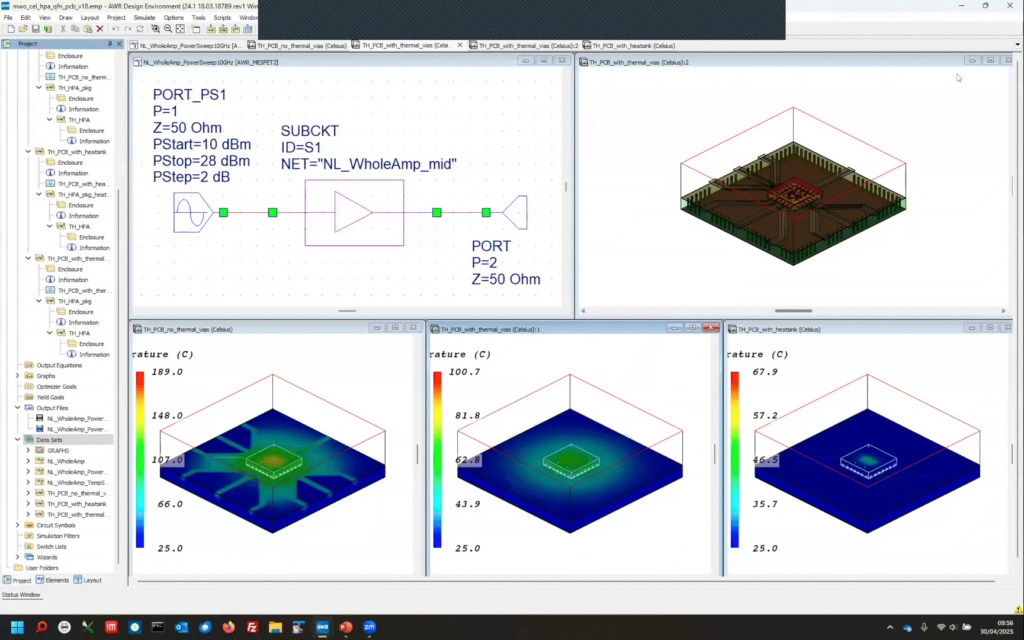

- What steps are taken to achieve an accurate controlled impedance design, such as material selection and stack-up design.

- How to ensure your stack-up is fabricated correctly the first time by communicating all the specific requirements to your manufacturer.

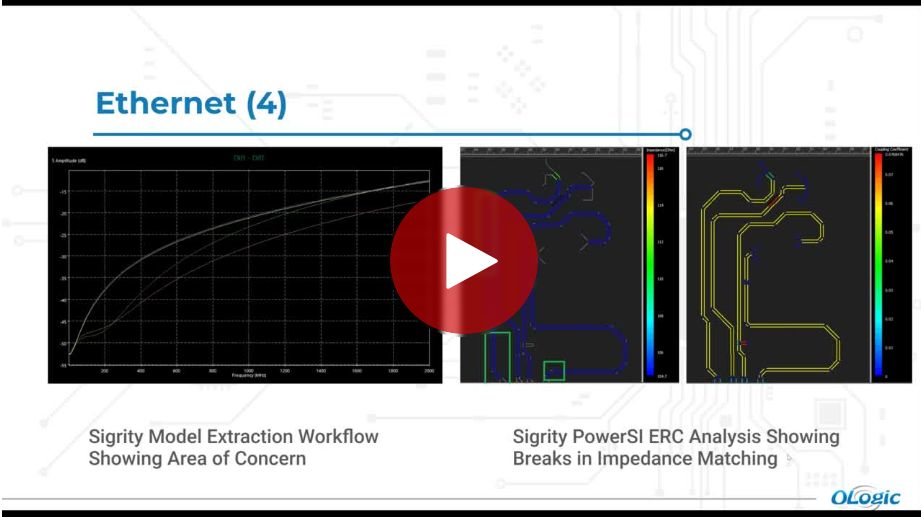

- Common causes of impedance discontinuities at the manufacturing stage and how to prevent them.

- How to define your impedance requirements in your CAD tool for real-time checking.

- How to evaluate for impedance discontinuities across your entire board before sending to your manufacturer

To view slides, click here.