It is difficult to argue against the many benefits that have resulted from cutting the electrical cord. Wireless technology has improved or enabled revolutionary advancements like the internet, cellular phones, and satellite communications. However, there are some applications where wiring and/or cabling are still the preferred option.

For hazardous environments, like automotive systems, the use of wired-technology like the CAN bus architecture provides reliable data communications. In addition to protection from environmental conditions, complex electrical connection routes can be bundled in harnesses and optimally placed for reliable signal and power transfer. Achieving these results begins with effective wire harness schematic design.

Wire Harness Applications

Wireless technology has the advantage of enabling long-range signal transfer, which extends around the world and even to and from space. However, for short-range transfer, wiring and cabling are more secure and less susceptible to external interference. And when multiple wires or cables are needed, wire harnesses allow for consolidation and organized distribution. These advantages are leveraged in a wide range of applications, some of which are listed below.

WHERE AND HOW WIRE HARNESSES ARE USED | |

Common Applications | Typical Uses |

Automotive Systems | Wire harnesses are common in cars, trucks, and other vehicles for signal and power distribution, as well as data acquisition (DAQ) and control. |

Computing and IT | Laptops, desktops, and other computing devices use wire harnesses internally and for interconnectivity. |

Telecommunications Centers | Large data centers use wire harnesses to connect servers, storage units and other equipment. |

Medical Devices | Complex equipment like imaging systems and portable medical care stations that require quick connect/disconnect are common harness uses in medical facilities. |

Housing and Buildings | Harnesses are used throughout housing and commercial building structures to organize and distribute power and communications (e.g. phone lines). |

Industrial Facilities | Power distribution to multiple units; such as production equipment, lighting, and safety systems are applications of wire harnesses in factories. |

Robots | Automation equipment like robots and cobots typically require multiple signal types and wires. |

As shown above, wire harnesses are utilized in a wide range of applications. In fact, any system that utilizes multiple signal types within an enclosed area or requires signal/power distribution in a hazardous environment is likely to deploy a wiring harness architecture. Realizing these benefits does present challenges, as listed below, that must be overcome.

Wire Harness Design Challenges

Designing wire harnesses is a challenging endeavor. The major issues that designers, engineers, and developers face are:

Challenges for Wire Harness Design

- Wire Harness Complexity.

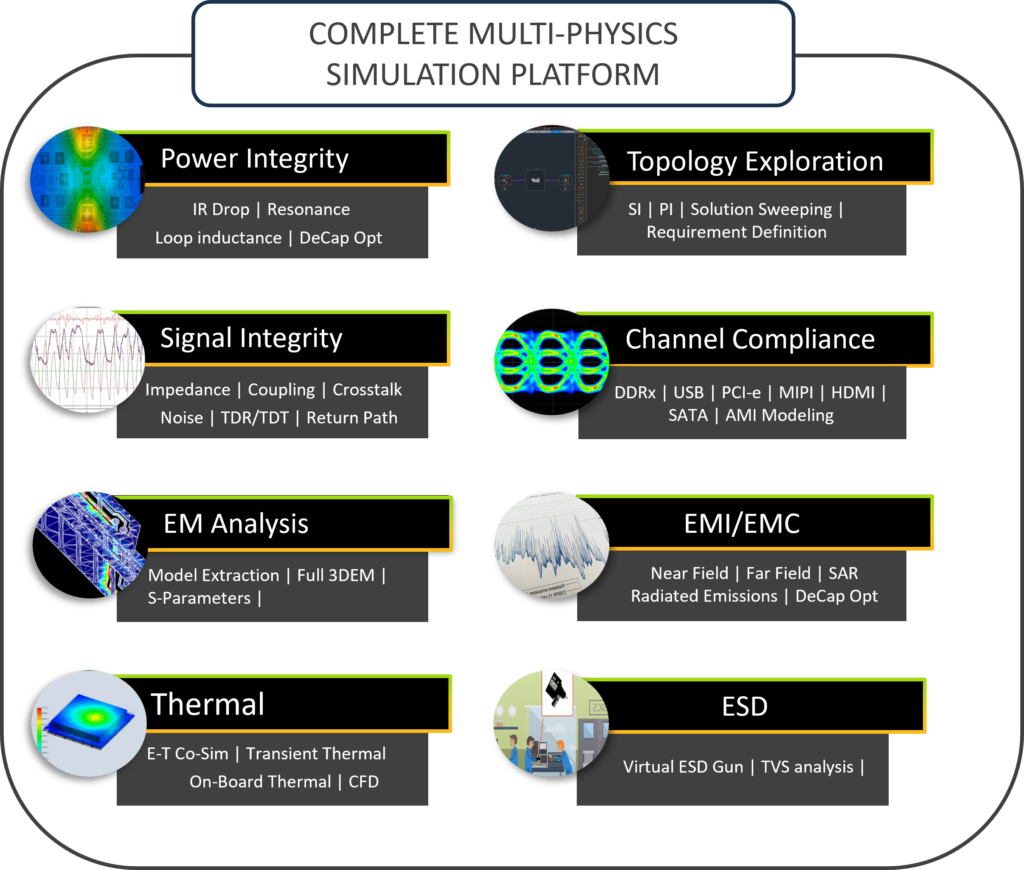

Wire harnesses often involve various signal types. For example, it is not common for wire harness to include power, RF and digital signals for distribution to multiple loads within the system. This can necessitate the need for complex network designs with varying physical and electrical parametric requirements. - Ensuring Standards Compliance

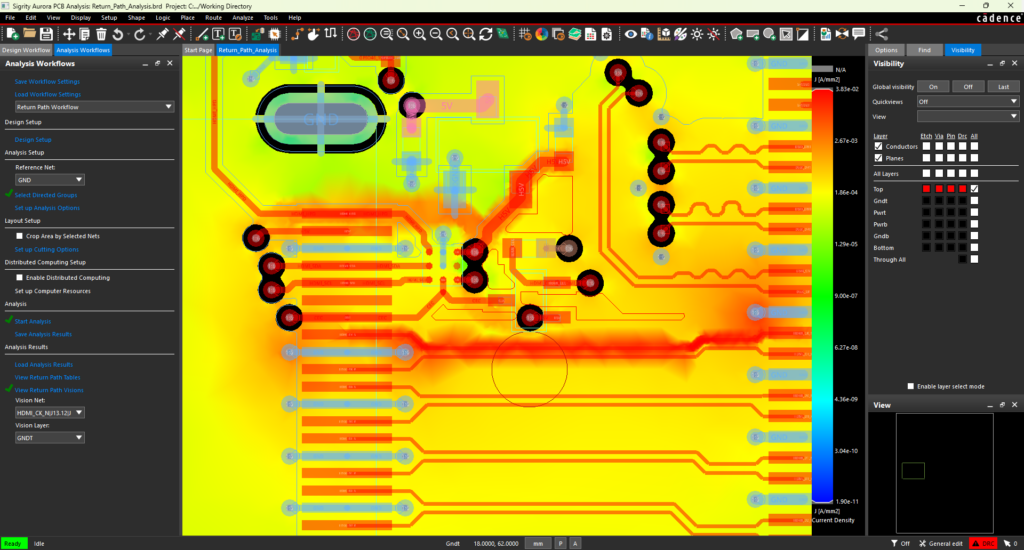

Wire harnesses must also be developed to adhere to electrical signal standards. These may include USB, MIPI, and/or HDMI compliance for signals, and National Electrical Code (NEC) for power, as well as others. - Data Integration.

Often wire harness designs require the integration of data from several sources. Ensuring that data is accurate and maintaining consistency is often daunting. - Team Collaboration.

Many wire harness designs are performed by engineers working in isolation from the rest of the team and may be using different and/or incompatible software. For example, ECAD and MCAD programs. When all sections are completed, they are combined into a final design, and there may be errors, inconsistencies, etc., that must be solved.

The above challenges can result in protracted wire harness design time and delays for new product development. The best way to address these issues is by instituting an optimization strategy at the wiring harness schematic design stage.

Wiring Harness Schematic Design Optimization

Although, implementing a wire harness solution is advantageous in challenging, local environments, there are significant challenges for effectively doing so. For any electrical/electronic system development, the design stage is the most important determinant of quality, reliability and process efficiency. Therefore, optimizing design must be a priority to achieve the best product development outcome. This is certainly applicable for electrical wire harnesses, and implementing the following during the schematic phase of design will result in more efficient design and improved product development.

How to Optimize Your Wiring Harness Schematic Design

|

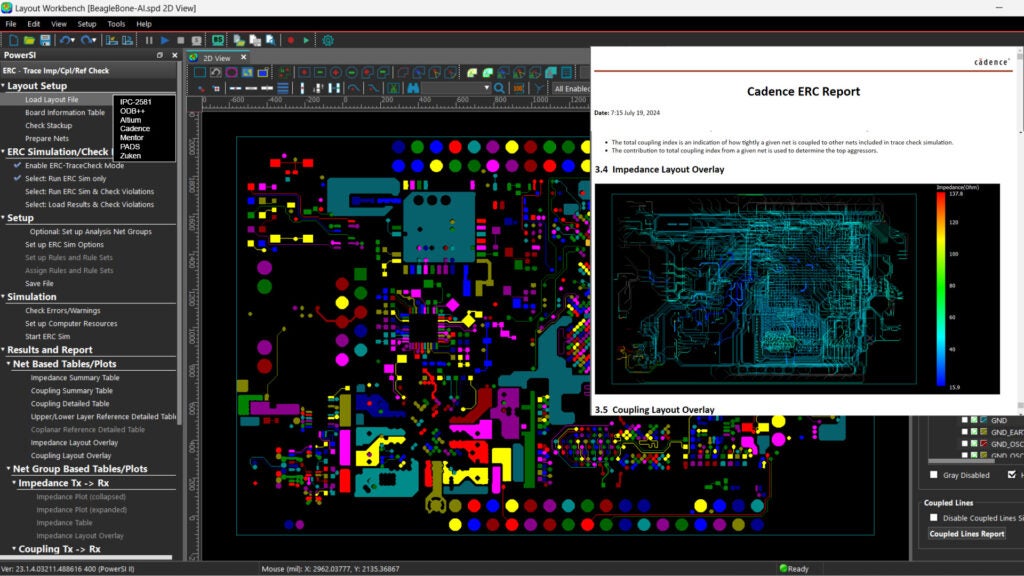

As the list above indicates, the quality of your design is directly related to the choices you make for product design and development software. To help you make the selection that will not only provide an immediate solution, but scale as your projects do, it is best to partner with an industry leader in supplying engineers and developers with the tools and support they need to satisfy their innovation needs.

EMA Design Automation is a leading provider of the resources that engineers rely on to accelerate innovation. We provide solutions that include PCB design and analysis packages, custom integration software, and engineering expertise, which enable you to create more efficiently. For more information on wiring harness schematic design and how we can help you or your team innovate faster, contact us.