Engineers use a variety of tools and resources to help them evaluate new components for their designs including: demo boards, app notes, co-worker references, FAEs, etc. This process can be tedious and require a lot of work and research to be done outside the standard CAD development environment—most of which cannot be re-used in production.

Helping to Improve the Component Selection Process

Many IC manufacturers are recognizing the need to help engineers speed up this process so they can quickly and effectively evaluate their parts before making a selection. As a result, web-based component evaluation tools have been made available on a number of IC manufacturers’ websites.

These tools provide a great way for engineers to get a feel for the vendor’s offerings and find which part(s) will best meet their designs needs quickly. As these tools have become more popular, IC manufacturers and customers have started to ask “How do I leverage my initial online evaluation in my production design?”

Two vendors, Texas Instruments and ST Microelectronics, are answering that question by integrating their online evaluation tools with PSpice to shorten the path to production for their customers. Below is a quick overview of the work done to date and how you can leverage these technologies when evaluating and selecting components from these vendors:

ST Microelectronics –eDesignSuite

STMicroelectronics is a global leader serving customers across the spectrum of electronics applications with innovative semiconductor solutions. STMicroelectronics eDesignSuite is a smart simulation tool that greatly simplifies the task of engineers working on various application types. Within eDesignSuite, users will be able to evaluate ST parts and modules with:

- Fully interactive schematics and BOM

- Bode, power-loss, and efficiency analysis

- Voltage and current-waveform simulations

- Export of evaluation design in OrCAD and PSpice

“OrCAD technology is a great way to enable our customers to test drive ST’s analog and power products,” said Carmelo Papa, Executive Vice President and General Manager, Industrial, and Multi-segment Sector, STMicroelectronics. “Evaluating our chips with the Cadence software will strengthen our customers’ confidence to have received the highest quality ICs needed for their success.”

You can learn more about eDesign Suite here.

Texas Instruments – WEBENCH

Texas Instruments is a leader in analog, digital, and mixed signal IC design and was an early innovator in the online component evaluation space and has a long history of innovation, creating tools to help engineers effectively find the right parts to match their unique needs.

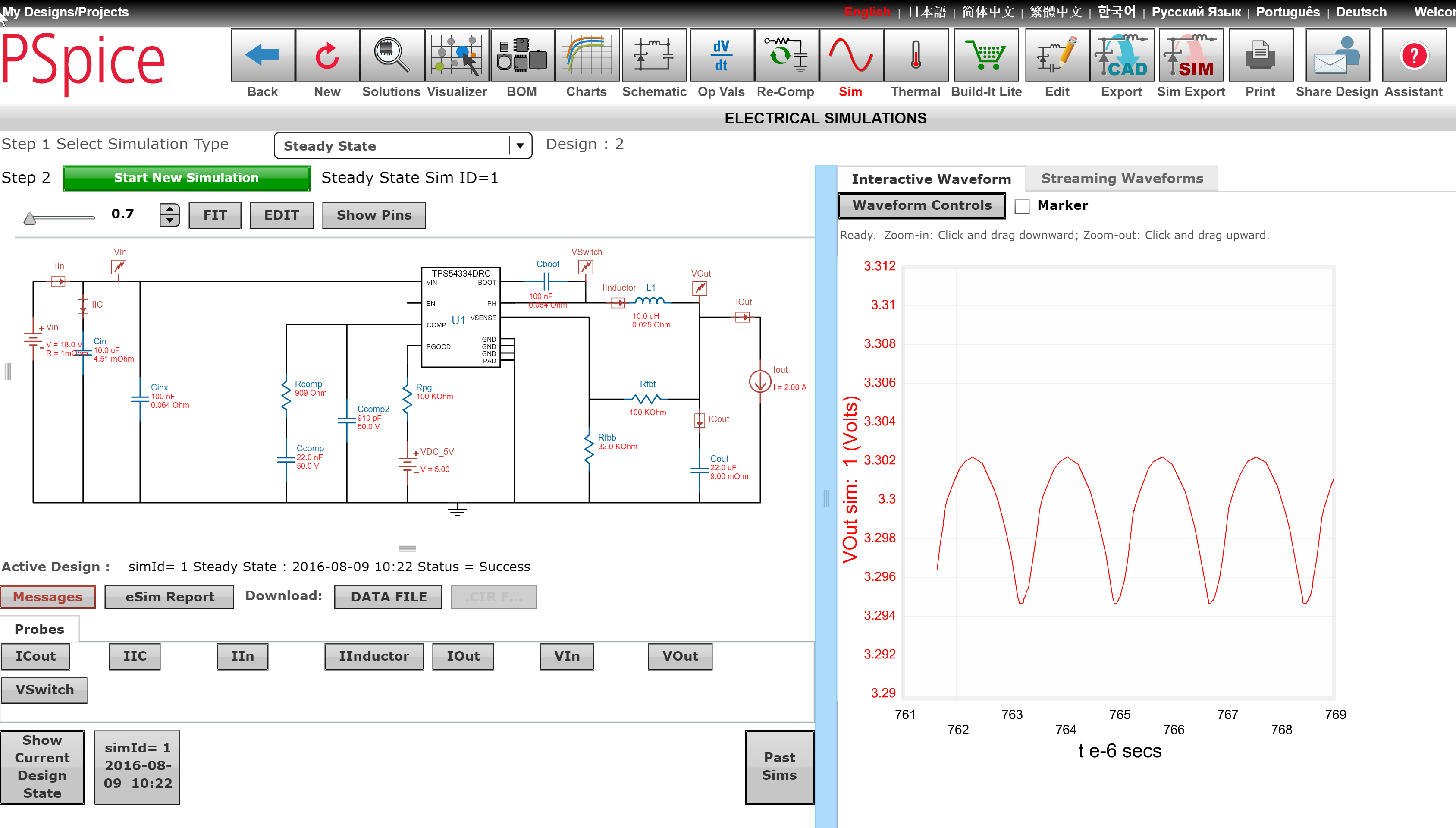

TI WEBENCH® Designer is a unique and powerful software tool that delivers customized power, lighting, filtering, clocking, and sensing designs in seconds. This allows you to make value-based tradeoffs at a design, system, and supply chain level before your design is committed to production.

WEBENCH tools use the latest component models, and easily export design files to the Cadence OrCAD environment. In addition, with the Simulation Export option in the WEBENCH tool suite you can instantly take your dynamically created, proven designs into PSpice for fast and easy simulation.

“The PSpice web portal and community is a good resource for any analog or mixed-signal engineer creating an electronic design,” said Makram Mansour, Ph.D., WEBENCH® Manager at Texas Instruments. “Within the PSpice.com environment, the designer can quickly create a sub-system design using WEBENCH design tools, select from thousands of component models, and easily export the simulation files to PSpice to characterize its performance. In just a few minutes, a designer can have a fully functioning sub-system board design and layout ready for fabrication.”

Users can access the TI Webench tool right on PSpice.com here.

Shortening the Path to Production

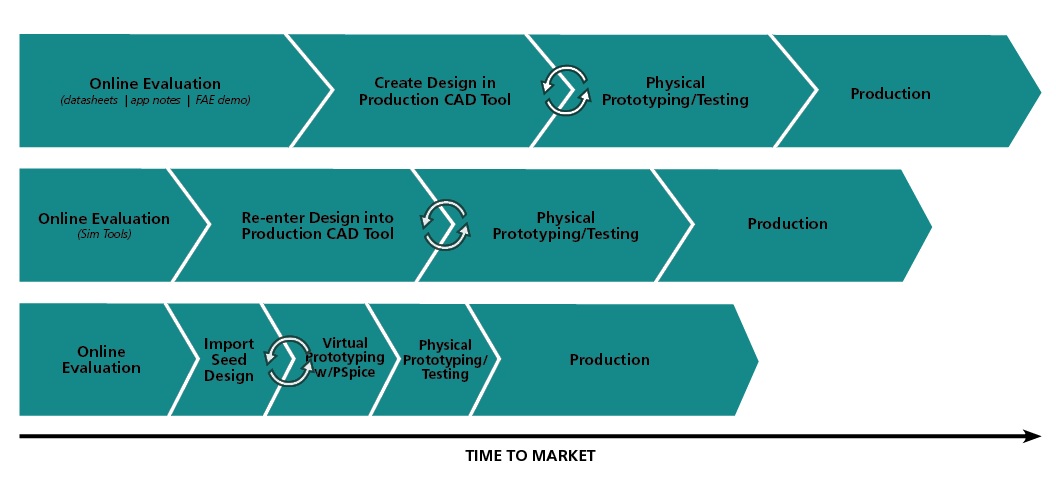

PSpice and these IC vendors are working to improve the development process for engineers, enabling them to quickly and effectively evaluate new devices while leveraging their initial analysis in their subsequent production design environments. By supporting early component and design evaluation engineers are able to make design trade-offs early, reduce the number of physical prototypes, and shorten the time it takes to get to production.

PSpice is the Standard in SPICE

Due to the popularity and capability of PSpice many IC manufacturers have chosen to develop PSpice models for their customers. These are just two examples of how IC manufacturers and Cadence are working together to help engineers reduce time to market and improve quality with simulation. In fact, PSpice currently includes over 34,000 ready to use models and that doesn’t cover the additional models available on the web and through the extensive model creation tools available inside PSpice itself.

You can learn more about PSpice at PSpice.com.