Industry 4.0, the latest revolution in tangible goods production, continues to be embraced by more manufacturing facilities. The result is that factories and their operations are becoming more innovative. For example, robots, machines, and other equipment can monitor and control processing, operations, and communication without human interaction.

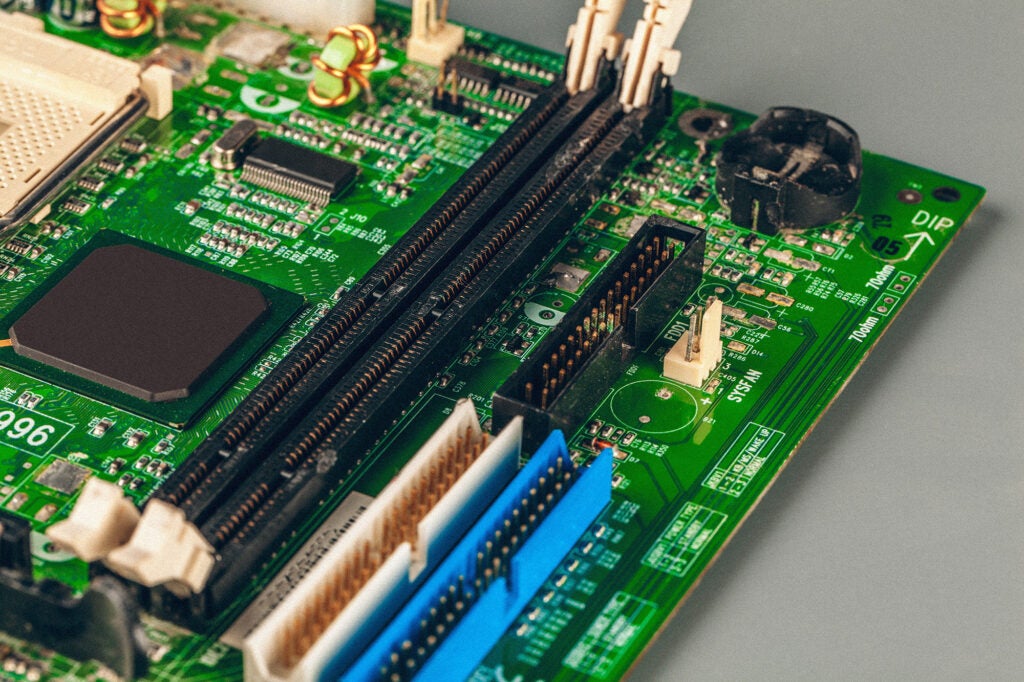

In many cases, IoT communication protocols define the network connectivity that enables the intermachine or machine-to-machine (M2M) data and information transfer. As is true for all IoT implementations, printed circuit boards are essential for the transmitter/receiver (TX/RX) and signal/data processing required for smart manufacturing. Due to environmental hazards, such as motion, vibration, and excessive heat, in addition to EMI/EMC concerns, IoT industrial design PCBAs must meet high standards.

What is IoT Industrial Design?

When employed in a factory setting, IoT is typically referred to as the industrial Internet of Things or IIoT, which has the following advantages for manufacturers.

Advantages of IIoT:

✅ Improve the efficiency of operations.

More automation lowers the possibility of human errors.

✅ Elevate the quality of products.

Less process error translates into better-built products.

✅ Raise manufacturing yield.

Better accuracy and higher efficiency mean less waste or unusable products.

✅ Stabilize the scheduling or production processing.

Higher yield enables more reliable scheduling and delivery.

✅ Minimize equipment downtime.

The transition to newer, more capable, and smarter machines reduces downtime.

✅ Increase overall equipment effectiveness (OEE).

Less downtime and higher yield allow factories to approach manufacturing capacities.

✅ Lower operational costs.

Better quality, greater efficiency, and higher yield lower overall operating costs.

✅ Promote innovation.

The availability of advanced equipment and technology offers opportunities for and motivates the pursuit of innovative products and processes.

Capitalizing on IIoT and realizing these advantages depends on the circuit boards and electronics that drive smart manufacturing, which must be designed to overcome the challenges of operating in an industrial environment.

IIoT PCBA Design Challenges

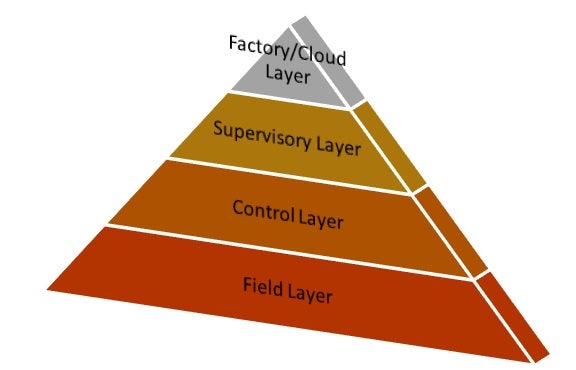

Circuit boards are utilized at every level of the IoT pyramid, shown below.

| PCBA Industrial IoT Design Types and Challenges | ||

| IIoT Pyramid Layer | Board Attributes | Design Challenges |

| Factory/Cloud | Networking | Reliable communications |

| Supervisory | Process monitoring and control | Programming and SW execution |

| Control | PLDs, controllers | Thermal dissipation |

| Field | Sensors | Accurate data acquisition |

As shown in the table above, designing PCBAs for the different IIoT levels requires that engineers focus on specific issues that affect design decisions and validation needs. This step ensures that the operation is reliable and performance objectives are met.

Factories also pose environmental challenges that must be overcome for IIoT PCBAs. These include the following:

IIoT PCBA Environmental Challenges

- Motion

Industrial machinery, including robots, often are constantly or intermittently in motion, which can cause shock and stress for PCBAs. This can result in tombstoning, the dislodging of surface mount devices (SMDs), or premature structural breakdown of the board. - Vibration

Another common attribute of faculty equipment that can create similar problems to motion is vibration. This issue is often inherent due to the electromechanical devices that drive processing equipment. - Excessive temperatures

High temperatures are common in industrial environments, especially when chemical processing is required. In most cases, this results in moisture in the atmosphere around the machine. If PCBAs are exposed, it can result in erratic performance, cause shorts, or even damage components. - Chemical exposure

As machines age, the risk of fluid leakages rises significantly. These spillages can have similar effects to moisture on circuit boards, which can disrupt and delay manufacturing and increase costs.

The advantages of IIoT are significant. However, your design process must include simulation tools and testing methods to mitigate or eliminate the above challenges.

Optimizing Your IIoT Product Development

Industrial PCBAs, similar to other critical industries like aerospace, automotive, and medical devices, often must meet the higher class 2 or class 3 performance requirements as stipulated in IPC 6011 and different industry standards. This is due to the environmental challenges these boards may be forced to operate in, and the precision and reliability required. Satisfying these challenges means your board’s ability to meet its application criteria and reliably operate in its installation environment should be proofed experimentally before deployment.

Although you will need to rely on your contract manufacturer (CM) or a testing facility for structural analysis or your built boards, you should utilize software tools to simulate your circuit’s operation during design to ensure performance and manufacturability, which will reduce the number of redesigns and respins necessary for bring up.

Simulations you should perform along with recommended tools are:

IoT Industrial Design Simulations

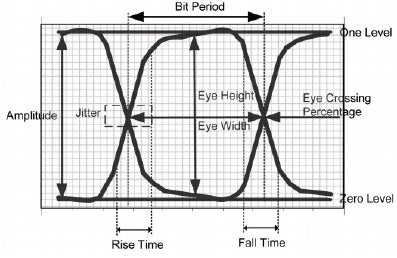

- Signal and Power Integrity Analysis

Sigrity, by Cadence, provides you with a comprehensive set of capabilities for SI, PI, and EMI analysis. - Wireless Network Analysis AWR allows you to evaluate your wireless network performance, including individual components, signal integrity, and communication protocols.

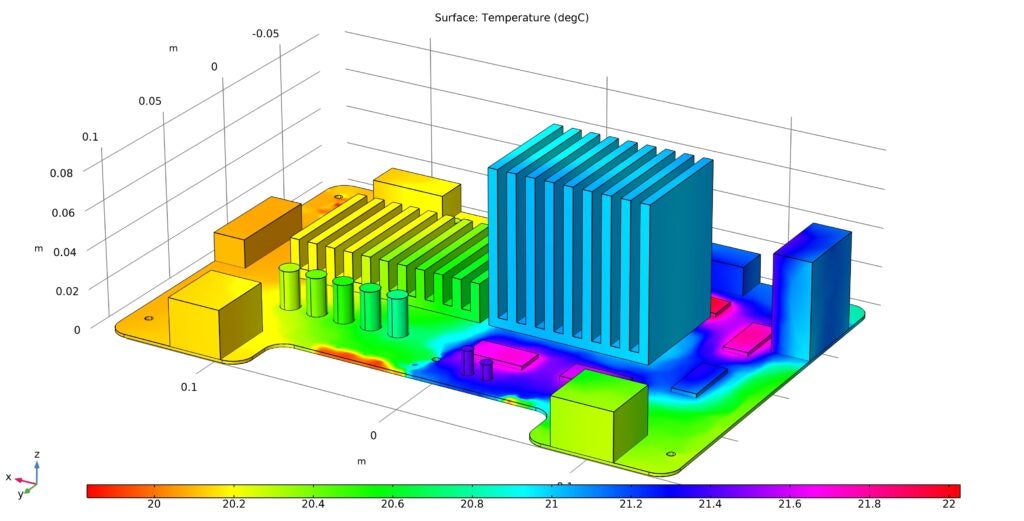

- Thermal Distribution and Dissipation

For temperature analysis, a Celsius Thermal Solver gives you advanced capabilities to aid you in designing your PCBA to operate safely for its industrial environment application.

By applying advanced tools to verify your board’s operation and performance, you can achieve an optimized development process and take advantage of the many benefits that IIoT delivers for industrial manufacturing.

EMA Design Automation is a leading provider of the resources that engineers rely on to accelerate innovation. We provide solutions that include PCB design and analysis packages, custom integration software, and engineering expertise, which enable you to create more efficiently. For more information on IoT industrial design and how we can help you or your team innovate faster, contact us.