There is no longer a serious debate about whether a double date rate (DDR) is better than synchronous dynamic random-access memory (SDRAM). Instead, the question is which DDR memory to implement for processor-driven electronics product development. Making the best choice for your PCBA design requires an understanding of the advantages and differences between DDR4 vs. DDR5.

.

Comparing the Features of DDR4 vs. DDR5

DDR memory, which Samsung first released in the late 1990s, has been utilized in the design and development of products such as desktop and laptop computers, gaming stations, networking equipment and servers, and other electronics products. Due to its faster transfer rates, wider channel density, uniformity, and consistency, DDR raised the bar for RAM. And these memory modules have been a major asset in expanding processor/controller-driven products that are now applied to products and systems across virtually all industries.

After several evolutions of functionality and capability improvement, today, DDR4 is the most widely used version. However, there is a steady increase in the implementation of the newer version, DDR5. Whether your objective is to optimize DDR4 or DDR5, understanding the specific features of each version, as given by the comparison below, is essential.

FEATURE COMPARISON OF DDR4 VS DDR5 | ||

FEATURE | DDR4 | DDR5 |

Year Released | 2014 | 2019 |

Transfer Rate | 1.6-3.2 Gbs | 3.2-6.4 Gbs |

Densities | 2Gb-16Gb | 8Gb-64Gb |

Prefetch width | 8n | 8n/16n |

Clock Type | Differential | Differential |

Strobe Type | Differential | Differential |

Supply Voltage | 1.2V/2.5v | 1.1V |

Interface Tech | POD | POD |

CAS Latency | 10-15 clocks | |

ODT | Yes-Dynamic | Yes |

As shown in the table, DDR4 and DDR5 do have some similar operational and performance specs. For example, both use differential clocks and strobe signals. Additionally, pseudo-open drain (POD) technology, which minimizes power consumption by eliminating the need for current to drive a high signal, is a feature of both DDR4 and DDR5. Nevertheless, there are implementation differences to consider when deciding which DDR version to implement for your PCB design.

DDR4 or DDR5?

As with every evolution of DDR, the latest version is designed to specifically improve functionality, operation, and performance in some areas. Although this is also true when comparing DDR4 vs. DDR5, there are reasons to choose each for your design, as shown below.

Advantages of DDR4

- Latency

Although DDR5 has a higher clock speed, DDR4 has a lower Column Address Signal (CAS) latency. In some cases, this can be as low as half as long. - Cost

The most significant advantage of DDR4 over DDR5 is its lower cost. This is especially significant when considering upgrading a legacy design, as the difference can easily translate into a substantially lower ROI for high-volume products.

Advantages of DDR5

- Speed

DDR5 has the advantage of a faster maximum data transfer rate: 6.4 Gbs compared to 3.2 Gbs for DDR4. - Module density

Module density is significantly higher for DDR5. At 8-64Gb, density is up to 4X DDR4, which ranges from 2-16Gb. - Lower power requirements

The power supply voltage for DDR5 is only 1.1V. This is down from 1.2V for DDR4.

The advantages and benefits above should be considered before settling on a memory module for your design. It is also important to understand the design challenges. Many of which are shared by DDR4 and DDR5.

Design Challenges for DDR Memory

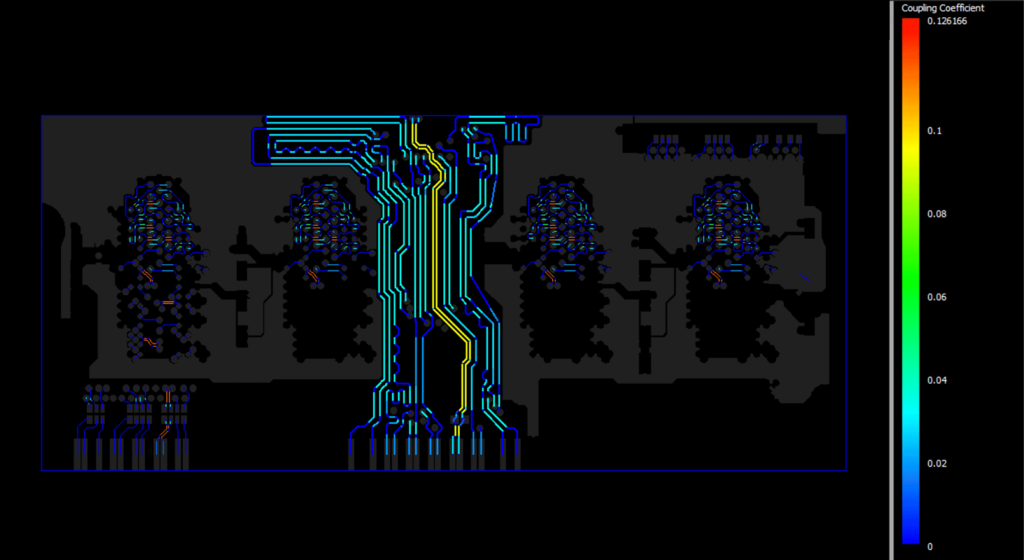

Signal integrity (SI) and power integrity (PI) issues are common concerns for PCBA designers. This is especially true when your design includes memory modules. For DDR4 and DDR5, the following challenges are of the most concern and can be difficult to solve.

DDR Memory Design Challenges

Understanding and Adhering to Constraints

Bit error rate or BER reports are a primary source of data utilized by JEDEC to evaluate memory data transfer quality. Consequently, it is imperative to know metric standards and constraints and ensure your design complies with these requirements.

Knowing and Achieving Timing Requirements

As speeds increase, the margin for timing error decreases. Delays due to buffering, package design and interconnects are targets to measure to avoid timing issues.

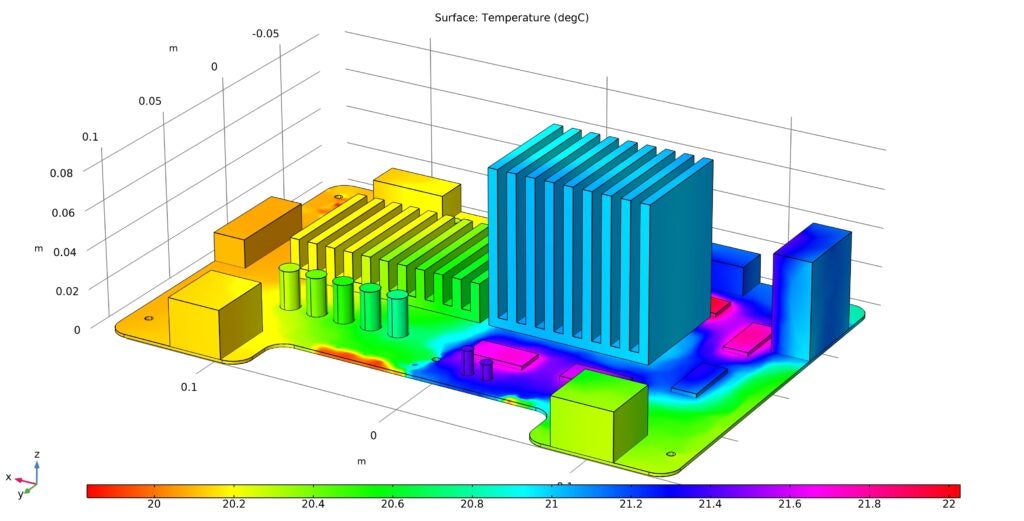

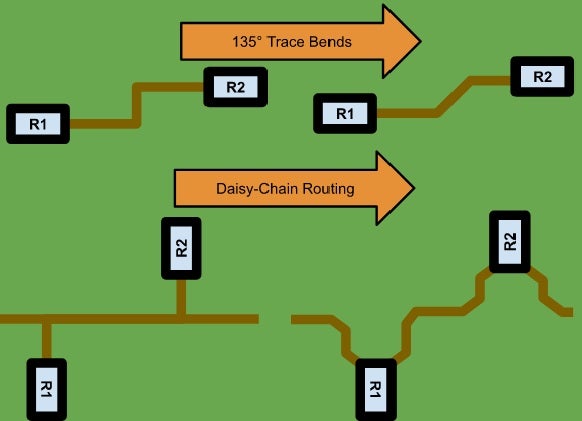

Optimizing Component Placement

Even for high-speed design applications, component placement is a major factor. Component locations and spacing define trace route lengths, establish the need for techniques like meandering–which is often implemented to ensure differential traces maintain matched impedance.

Verifying Functionality and Compliance

The best method for analyzing functionality and evaluating compliance during design is to maximally leverage masking to test jitter and noise margins, as well as skew rates and slew rates.

The design challenges above apply to both DDR4 and DDR5. And the solution for both is DDR memory compliance testing.

Ensuring DDR Memory Compliance

The Joint-Electron-Device-Engineering-Council, or JEDEC, is a globally recognized standards organization that publishes regulations and guidelines for DDR4 and DDR5 memory modules. Satisfying these standards, as well as overcoming the DDR design challenges that come with implementing these components, requires not only knowledge of PCBA DDR design best practices, but also the ability to validate DDR compliance. The best way to ensure that your built circuit board will achieve compliance and meet your performance objectives is by software verification during design.

For help testing and verifying SI for DDR interfaces, see these additional resources:

- How to verify SI for DDR interfaces.

- DDR signal integrity metrics check.

- Simulating and validating DDR5 interfaces.

- DDR5 post-layout verification.

The best option is to rely on an industry leader in PCB design and development software solutions, including DDR testing tool applications, to aid you in avoiding common memory issues and ensuring a DDR-compliant design. Doing so will optimize your PCBA development process by minimizing or eliminating unnecessary time loss and cost.

EMA Design Automation is a leading provider of the resources that engineers rely on to accelerate innovation. We provide solutions that include PCB design and analysis packages, custom integration software, engineering expertise, and a comprehensive academy of learning and training materials, which enable you to create more efficiently. For more information on choosing between DDR4 vs DDR5 and how we can help you or your team innovate faster, contact us.