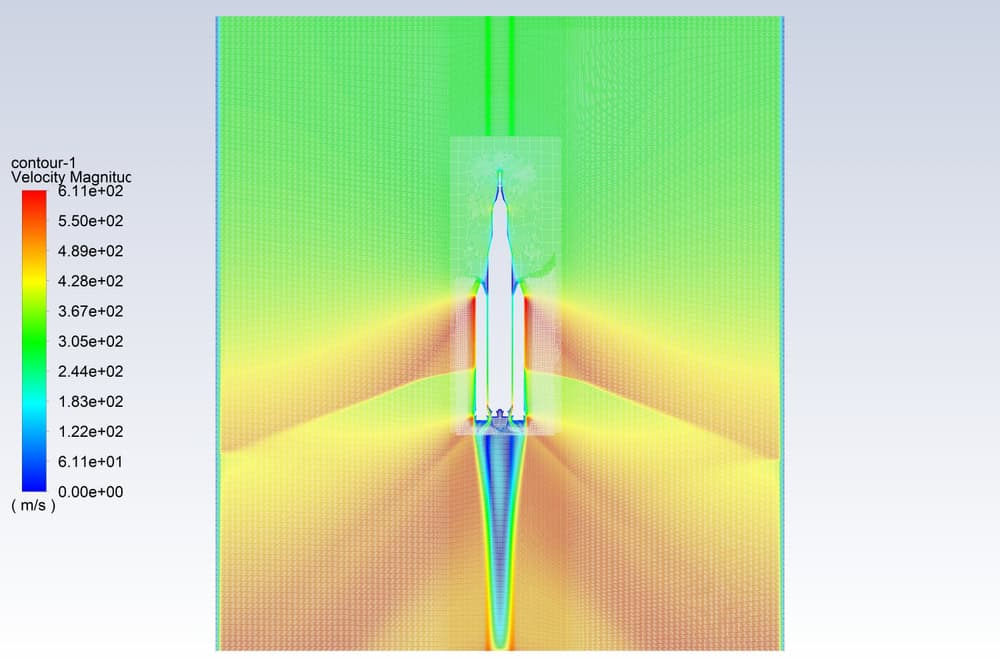

Fluid flow, which includes gasses like compressible air, is one of the most important physical phenomena that must be considered for systems in motion, like rockets. Whether in a terrestrial, marine or space environment, accurately analyzing and designing your vehicles to overcome and/or offset the opposing effects of fluid flow is critical for effective performance. Therefore, computational fluid dynamics or CFD analyses are critical for exterior system design.

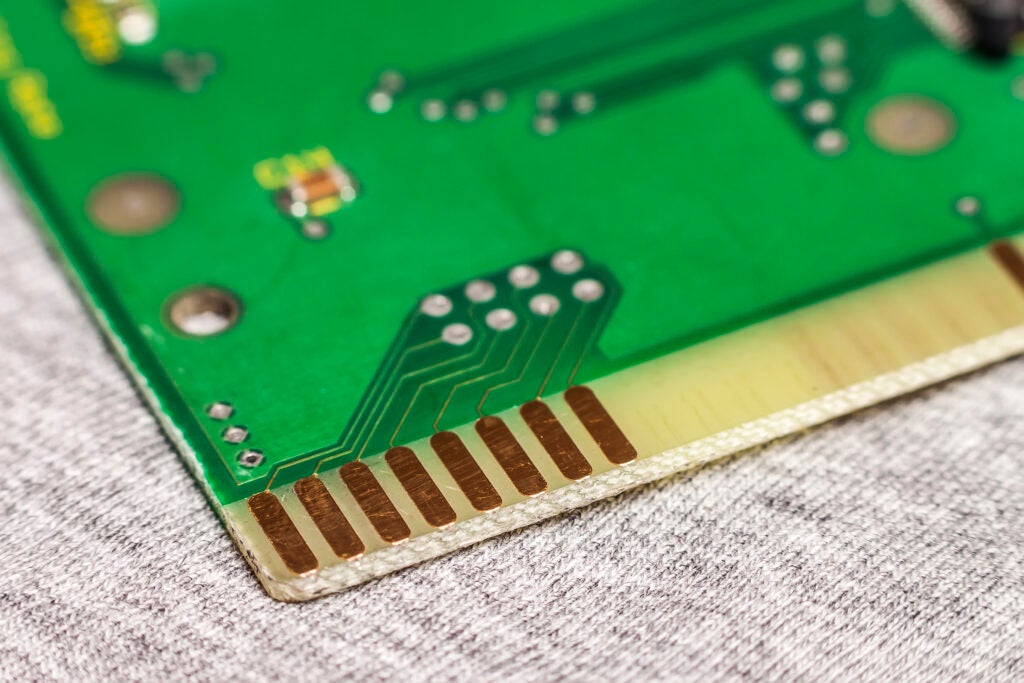

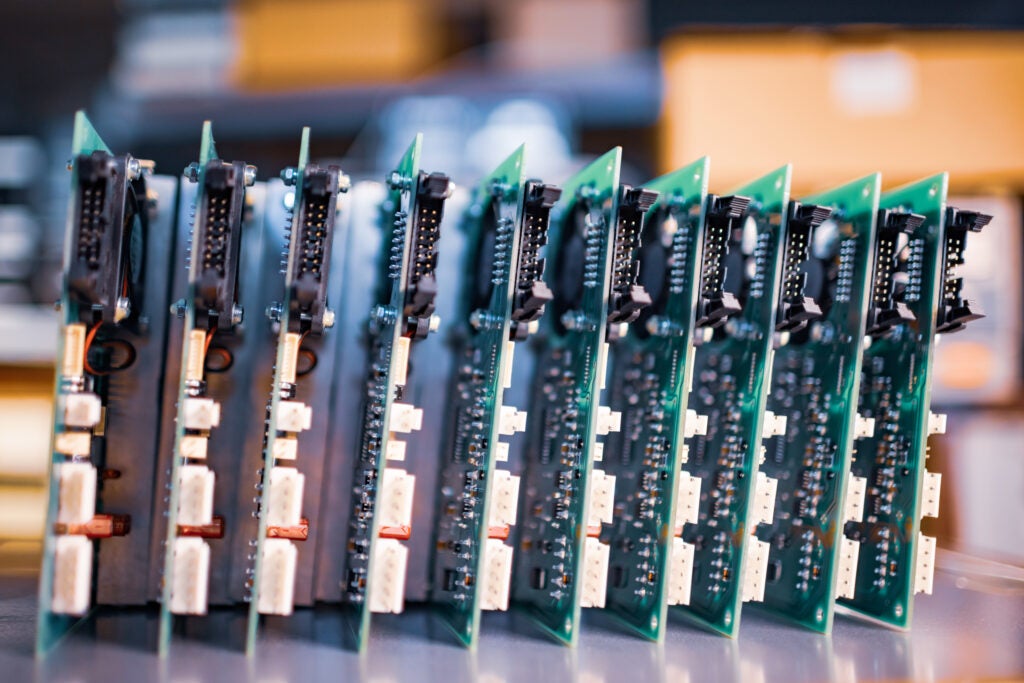

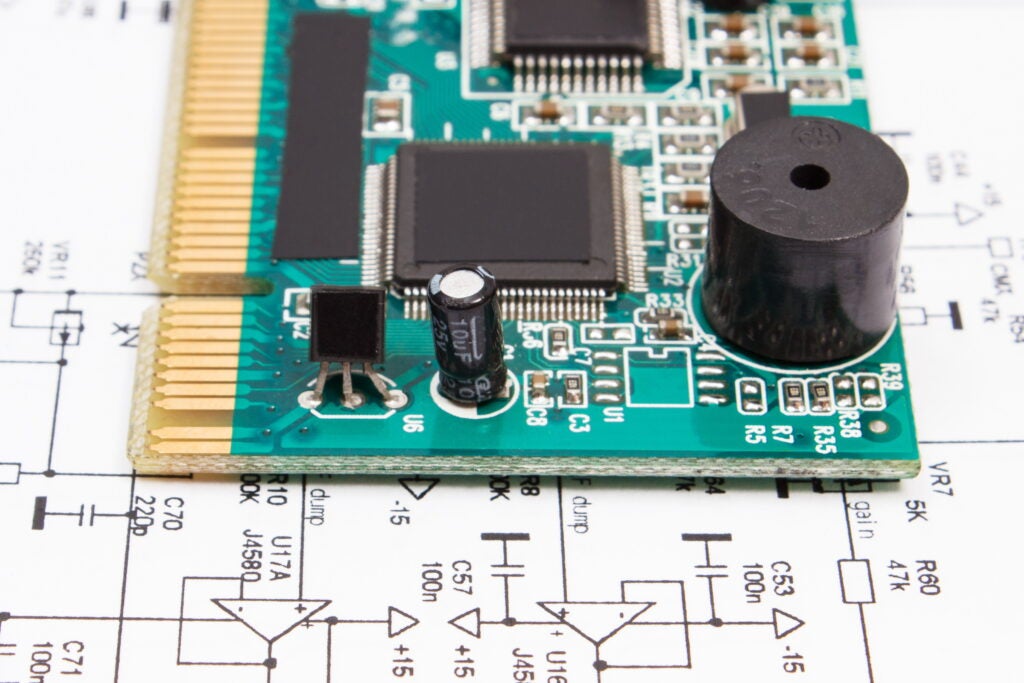

CFD analysis is also important for interior system design. In this case, the most critical issue is heat flow. The ability to distribute and dissipate excess heat is a major concern for electronic systems; including circuit boards that comprise virtually all automotive, marine and aerospace systems. As most PCB design programs do not include this capability, it is important to follow guidelines when making a CFD simulation software comparison for integration with your EDA tool.

CFD Simulation Software Comparison: Attributes and Uses

Choosing the best CFD software tool for your PCB design and development begins with knowing the best simulation tool options and how they are commonly used.

CFD Simulation Software Comparison | ||||

CFD Software | Key Attributes | Common Applications | ||

| Turbomachinery modeling, analysis and design, integrated marine system analysis, propulsion system analysis | |||

| Aerodynamic analysis and design and fluid flow optimization for automotive, aerospace and marine system. | |||

| Thermal analysis and dissipation/distribution optimization for electronics systems. | |||

| Large structure problems, complex aerodynamic and aeroacoustic simulation, multibody system simulation | |||

| Electronic cooling, data center and lighting design, HVAC for AEC/MEP | |||

Each of the CFD simulation software programs above has advanced analysis capabilities that collectively target the full range of fluid flow and thermal issues that PCB designers and engineers may encounter. The challenge is choosing the solution that best meets your design needs today and in the future.

CFD Simulation Software Essentials

When deciding on the CFD simulation software that is best for your design requirements, it is important to follow good guidelines, as listed below.

Optimizing Your CFD Simulation Software Implementation

- Clearly define your CFD problem space

The first step of your CFD simulation software comparison is to know the types of problems you need to analyze. This should not only accurately represent current projects, but also future projections.

- Choose a CFD program developed with an emphasis on electronic system design problems

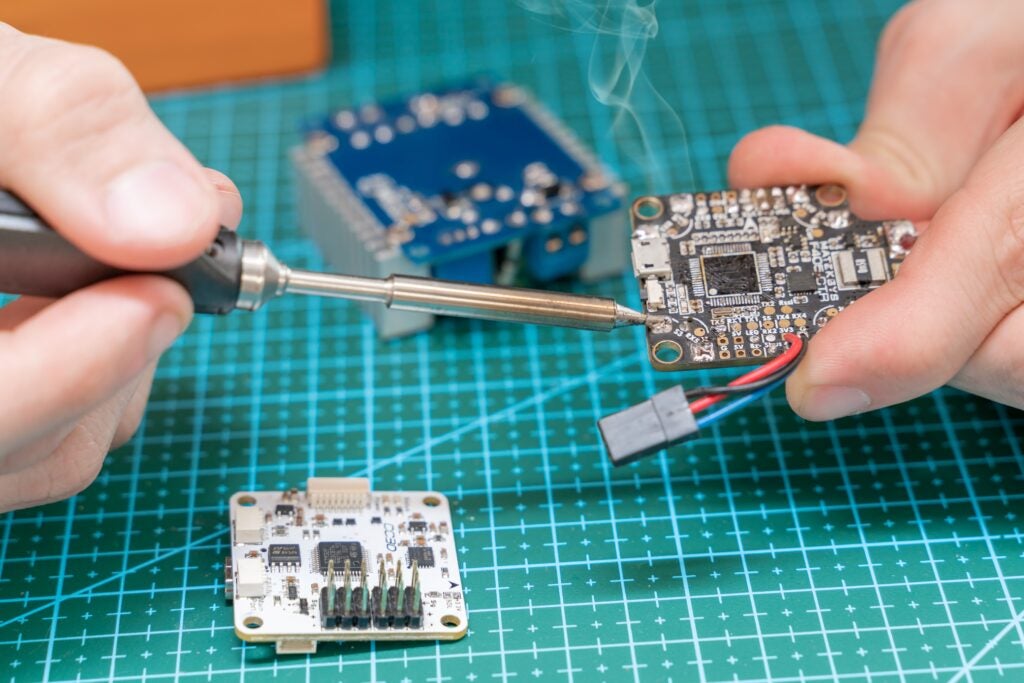

Fluid flow is a natural phenomenon. However, different system types may have somewhat different primary concerns. For example, heat dissipation and cooling are major concerns in high-power electronic design, but not as much for skin or surface mechanical structures. See this webinar for more information on solving thermal challenges in your design.

- Select CFD simulation software that integrates with your EDA tool(s)

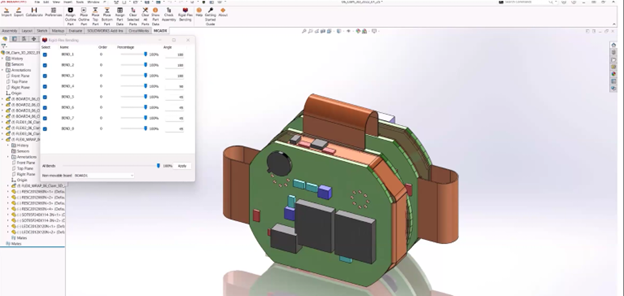

File format compatibility is essential when integrating with a CFD program. Although converters exist for the most common 3D model formats, there is always the possibility of an error or missing information when your EDA tool and CFD program are not built to work with the same data formats.

- Ensure that your CFD software will scale with you

An often-overlooked issue when using any PCB design software support tool; including CFD software, is scalability. Having to change CFD solutions as your design challenges do can be time-consuming and costly.

Following the guidelines above will help you perform an effective CFD simulation software comparison. However, the best option when choosing a CFD tool is probably to rely on a partner that has experience in creating software integrations with electronics industry leaders to optimize your CFD tool utilization.

EMA Design Automation is a leading provider of the resources that engineers rely on to accelerate innovation. We provide solutions that include PCB design and analysis packages, custom integration software, engineering expertise, and a comprehensive academy of learning and training materials, which enable you to create more efficiently. For more information on CFD simulation software comparison optimization and how we can help you or your team innovate faster, contact us.