It is no secret the advent of the COVID-19 pandemic has affected all industries. Supply chain shortages have made it hard for medical personnel to get the supplies they need. All over the world, people are working to find a way to help lessen this burden. From distilleries creating hand sanitizer and photography manufacturers creating face shields, everyone is coming together to help support their communities.

After hearing about companies in Italy supporting their local hospitals by making ventilator valves, Mike Brown, CTO of Alliance PCB Solutions and Alliance 3D felt the need to act. While he considers himself a ‘PCB guy’ first and foremost, he decided to call upon his mechanical background to help solve the PPE shortage here due to COVID-19.

3D Printing Fills the Supply Chain Gap

3D printing is changing the landscape of supply chains. With the reshoring of American manufactured goods, there is an increased gap in the manufacturing process between prototype and low volume production. Seeing this issue, Mike and the team at Alliance PCB knew they could streamline the manufacturing process with 3D printing, which led to the creation of Alliance 3D.

“We decided to go into the mechanical side and add a 3D print farm because we recognize there is a gap in the manufacturing process…” Mike explained. “ [Now] we can delve into, some other opportunities with the 3D, mechanical modeling, engineering and 3D print manufacturing.”

The Citadel Safe Mask Initiative and the Fit-to-Face Mask Design Challenge

When Citadel Military College of Charleston’s Safe Mask Initiative, started using 3D printers to create masks as donations to the Medical University of South Carolina (MUSC), Mike joined in. “We saw some local articles where they were reaching out to the makerspace and right at that time, we were designing our own mask…” he said. “So we reached out to them … [and in] just about two weeks’ time, we produced roughly 100 mask kits for them.”

When Citadel Military College of Charleston’s Safe Mask Initiative, started using 3D printers to create masks as donations to the Medical University of South Carolina (MUSC), Mike joined in. “We saw some local articles where they were reaching out to the makerspace and right at that time, we were designing our own mask…” he said. “So we reached out to them … [and in] just about two weeks’ time, we produced roughly 100 mask kits for them.”

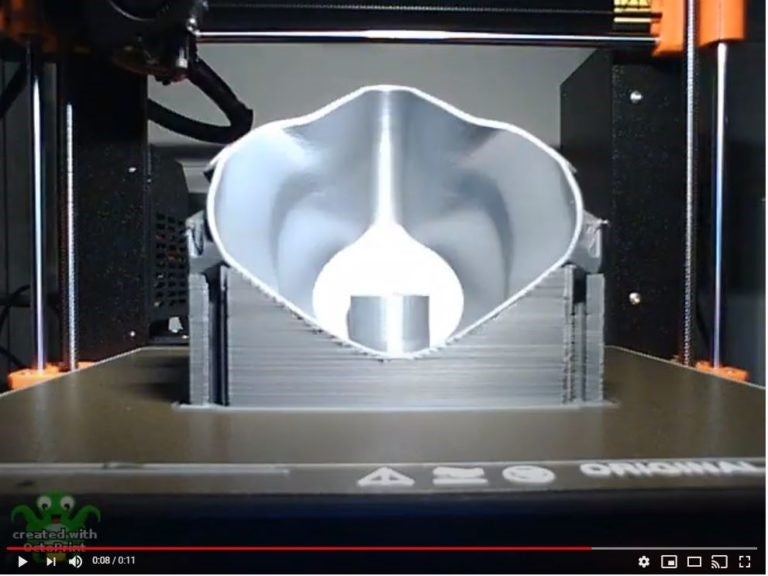

Through his work within this initiative, Mike discovered the Fit-to-Face Mask Design Challenge from America Makes, where his mask design, the Vader II, placed as the top design among nearly 600 applicants. According to the America Makes website, The Fit-to-Face Mask Design Challenge was a five day challenge that called on designers to quickly create and/or modify 3D printed face mask designs to fit a wide range of faces while improving continuous fit-to-face contact and providing safe sealing between mask and skin.

“They were looking to see if masks can actually be 3D printed, and solely 3D printed, in hopes the makerspace could help supplement the additive manufacturing supply chain and help conventional supply chain shortages,” Mike explained.

About the Design

To help Designers get started, America Makes provided 5 different head scans/sizes from the National Institute for Occupational Safety and Health (NIOSH) to identify the contour needed to create a universally-fitted mask: small, medium, medium-wide, large, and long. Mike took his initial base mask (called Vader because according to Mike, it looked like a Darth Vader mask) and reworked it for his entry, the Vader II.

“We found some commonality between the nose, the cheekbone, underneath the chin, and between the chin and lip line. Then from there, we started coming up with additional design concepts that we were literally designing and printing in real-time…so within 5 or 6 hours we had a print we could review,” Ultimately, he decided on a hybrid construction, with a more flexible material on the outside.

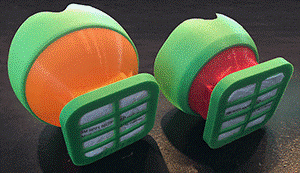

While the main aspect was to make the piece 100 percent 3D manufacturable, there were other aspects to consider including post-processing, assembly time, and reusability. The Vader II is not only 100 percent 3D manufacturable, but it requires no post processing time, takes less than 30 seconds to assemble, and is completely reusable.

Next Steps

With the Vader II placing in the top designs, it has undergone further VA and NIH testing per FDA clinical guidelines. Alliance 3D received positive feedback with regards to form, fit, and function. Currently, the Vader II is being used under emergency medical use to help combat the rising PPE shortage. 3D Models and printing instructions are available for free download under creative commons licensing.

Mike, Alliance PCB solutions, and Alliance-3D have vowed to provide COVID-19 support to Citadel, MUSC, and their community for as long as the need is there. “We feel as though this could have a huge impact on assisting the medical arena as well as people overall,” Mike said. “Hopefully, we’ve come up with a solution that everyone could wear at one time.”

In the meantime, Mike and the Alliance-3D Team are working to further expand their presence in the Additive Manufacturing Space, providing 3D Print Farm and Mechanical Design Engineering services.