Electronic Component Research and Selection

During the schematic creation and part selection process, every component in the design needs to be reviewed and analyzed to guarantee adherence to project requirements. The part selection process is typically comprised of:

- Researching a component

- Comparing component parametrics to design requirements

- Documenting purchasing information

- Gathering additional resources to help with the design process

- Incorporating the component into the design

While this is critical to design success it is also time consuming, especially for large designs with hundreds of components. To help speed up electronic component research and selection, we’ve compiled our top 5 tips to ensure designers choose the best parts for their designs quickly.

Identify Key Reliable Sources for Part Information

Information is only as good as it’s source. When sourcing part information, it’s important to reference trusted sources which provide reliable information including component parametrics and supply chain data. Examples of reliable sources include:

- Distributors

-

Trusted distributors, such as Digi-key, Mouser, etc., can be used as a reference for parametric information as well as purchasing information. Sourcing components from these reliable distributors will ensure timely and cost-effective component procurement.

- Supply Chain Vendors

-

Supply chain vendors, such as SiliconExpert, are a reliable source of information to determine component risk, compliance, lifecycle information, and more.

- IC Manufacturers

- Industry Partners

With counterfeit parts on the rise due to high-demand and low inventory, going to directly to the manufacturer will ensure accuracy of parts and information.

Industry partners want you to succeed and often provide tools and information for you to do so. Industry partners can be CAD vendors, PCB manufacturers, industry guiding bodies, and more.

Know Your Criteria

Once you have selected your reliable source(s) for component information, it’s time to sort through all the provided data. While there is often a plethora of information to review, to accelerate the part selection process you must sort out which information is important for your design.

- Function and Performance Metrics

-

- Price

-

- Quantity and Availability

The first and most important criteria is the function and performance metrics for the component. Metrics such as voltage rating, operating temperature, tolerance, etc. should be analyzed to determine if the component adheres to the design specifications.

Staying within the budget constraints of the project is a measurement of its success. Many factors contribute to a components price and there may be some tradeoffs to consider when selecting a component. For example, tighter tolerances result in higher prices. If design performance is not affected, selecting a similar component with a loosened tolerance will save money. There could also be price breaks for certain quantities or packaging.

-

- Compliance

Is the required quantity available immediately or will you need to wait for the component to be produced? If the quantity is not currently available, you will need to look at the minimum and maximum lead times for the component. Selecting a component with a higher lead time may impact the project timeline and desired release.

-

- Lifecycle

Does your project need to comply with environmental and regulatory standards? If so, these criteria need be addressed and reviewed at the component level. Common information to review includes RoHS, Reach, and conflict mineral compliance.

Selecting a component that is nearing the end of its life, such as components labeled as Not Recommended for New Designs (NRND) or Last Time Buy (LTB), may result in unintended design revisions if a component cannot be sourced. Analyze the lifecycle of the component to determine the part status, years to end of life, and predicted obsolescence to guarantee alignment with the project goals and specifications

Identify Backups Whenever Possible

With the volatility of the electronic supply chain, it can be beneficial to plan for the worst. Determining backups will help guarantee project success with minimal hiccups. Backups should be defined for both sources and critical components.

- Multi-source

-

Define multiple sources for your components. If a component becomes unavailable, having an alternate distributor defined will provide a secondary purchasing option and keep the design on-track. The same can be achieved by defining multiple manufacturers for generic or common parts.

-

- Crosses

If a part becomes unavailable, is there another component that can be used as a direct replacement? Component crosses or alternate components should be evaluated, especially for critical components in the design. Often crosses are given a grade depending on the similarities to the original component, providing insight into the design modifications required to swap out the components.

Check for Additional Key Data to Speed Up the Design Process

When selecting a component for the design, one factor to consider is the supportive material provided by manufacturers and industry partners. Additional component resources and key data can help accelerate the design process. Designers should assess and gather common resources including:

- CAD Models

- Simulation Models

-

- Application Notes

Creating CAD models can be time consuming. Sourcing verified symbols, footprints, and 3D models will allow you to reallocate time spent on model creation back into the design.

Verifying circuit functionality before prototyping and PCB production can be achieved through simulation. For accurate circuit analysis, many manufacturers provide verified simulation models.

-

- Reference Designs

Application notes can provide helpful tips and information for designing with the selected component. These can be referenced throughout schematic creation. Application notes and design information are often included in component datasheets but can also be separate documents associated with the component.

-

- Compliance Documentation

Some manufacturers provide reference designs to showcase the capabilities of their components. Reference designs typically include pre-defined solutions which designers can use to accelerate product development. Manufacturers may provide schematics and/or PCB layouts in various CAD tool formats as a starting point for designers.

To prove compliance to industry or environmental standards, you may need to gather compliance documentation such as material declarations or compliance certificates

Bring Part Research and Selection Together

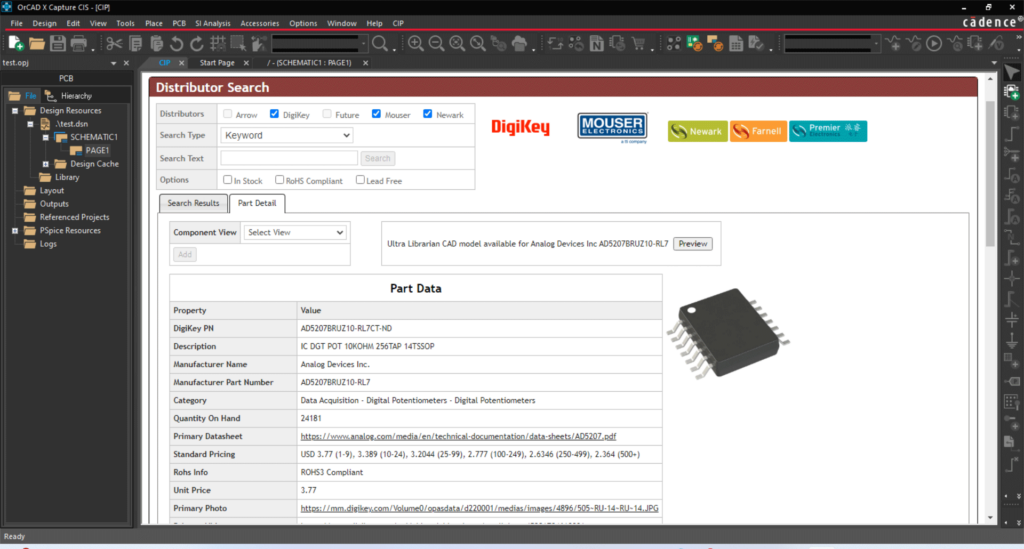

Manually managing all the information required for part research and selection can be overwhelming and error prone. Bring part research and selection together with OrCAD CIP. OrCAD CIP provides an efficient method to manage your component database with direct integration between your CAD environment and distributors. This allows you to:

-

- Perform part research within your CAD tool

-

- Review real-time supply chain and parametric information from trusted, reliable distributors

-

- Link multiple sources and manufacturers to components

-

- Associate pre-built symbols, footprints, and 3D models to components

-

- Manage all associated data in one location (models, datasheets, etc.)

-

- Eliminate manual entry of parametric data

-

- Automate the new part introduction (NPI) flow

Learn how to create a centralized environment for electronic part research, selection, and management to streamline the design process and unlock the key to design success with OrCAD CIP.